After allowing the filtered grease to settle for the weekend, we noticed that there was a lot of water that settled on the bottom. This was perhaps a cause of the cloudiness of the waste grease.

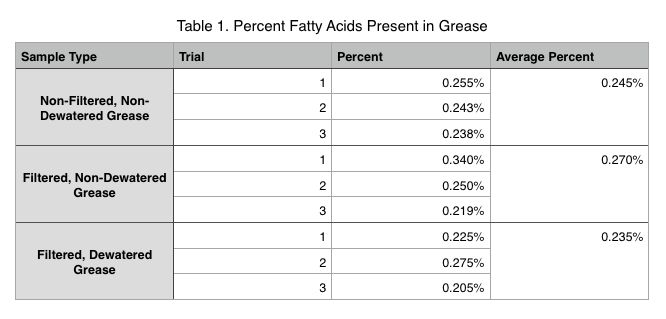

During the lab period this week, the group was able to work on dewatering and testing the fatty acid number of the waste grease. We tested three trials of three different samples of the waste grease. The three samples were the unfiltered waste grease, the filtered waste grease before dewatering, and finally, the filtered waste grease after dewatering. In order to test the fatty acid number, a simple titration was completed.

All of these values for percent fatty acids present in the grease are very similar which makes sense because all of the grease is from the same sample and even those that have been filtered and dewatered still contain the same amount of fatty acids present. The small differences are due to experimental error and, perhaps, not using large enough samples since our values are so small.

In order to dewater the filtered waste grease, it was placed on a hot plate and constantly stirred. The temperature of the oil was held to around 95 degrees celsius. This was to prevent the water from boiling off too quickly, causing the oil to splatter.

Figure 1. Unfiltered waste grease

Figure 2. Filtering of waste grease in gravel filter.

Figure 3. Filtering of waste grease in the small gravel filter.

Figure 4. Waste grease after gravel filter.

Figure 5. Single layer cheesecloth filtering.

Figure 6. Waste grease after filtering through single layer of cheesecloth and gravel filter.

Figure 7. Waste particles that collected on single layer of cheesecloth.

Figure 8. Final filtering of oil through cheesecloth (5 layers).

Figure 9. Waste grease after final filtering (final product, ready for dewatering).

Figure 10. All three samples of the waste grease. Before filtering (left), after filtering (center), and after filtering and dewatering (right).

No comments:

Post a Comment